Crude oil desalting

Removing salts and solids from crude oil is critical to refinery production efficiency. This put high demands on the heat exchangers. Proper cooling of effluent water is also required for further treatment in waste water plants. No matter the fouling tendency or corrosiveness of your desalter effluent, Alfa Laval heat exchangers secure maximum heat transfer efficiency and heat exchanger uptime.

Improving crude oil desalting processes

Reducing the salt content of the treated crude oil to acceptable levels creates high fouling throughout the process. To minimize downtime and optimize effluent cooling, low-fouling Alfa Laval heat exchangers are an excellent choice.

Increasing energy efficiency in refinery desalting processes

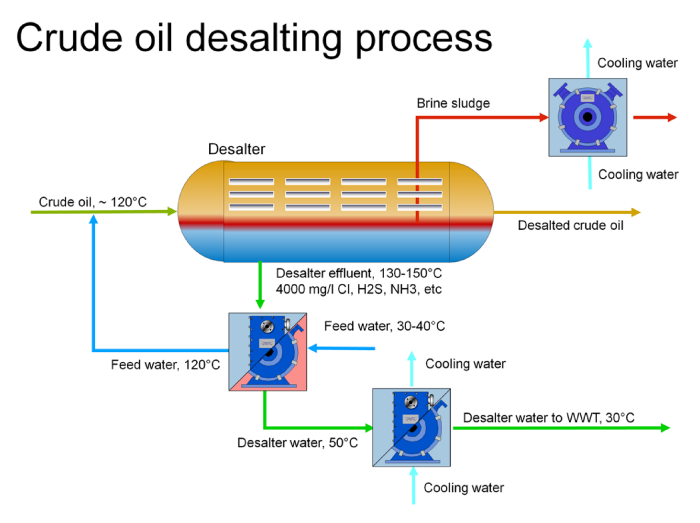

Recovering energy from desalting effluent water serves two purposes. Firstly, energy recovered is used to preheat feed water to the desalter in order to increase process efficiency. Secondly, it effectively cools the effluent water prior to treatment downstream at the waste water plant. Fully counter-current Alfa Laval heat exchangers that provide a close temperature approach of 5°C make it possible to maximize heat recovery.

Fouling mitigation in the desalting process

Fouling in desalter exchangers has a negative impact on energy recovery and, if the effluent is not properly cooled, it will enter the waste water treatment plant at a temperature that is too high for waste water processes and therefore may cause upsets.

There are different types of fouling, including salt deposition over time, sludge plugging during mud washing, or an oil film that covers the heat transfer surfaces thereby reduce heat transfer efficiency.

Depending on the nature and the severity of the fouling, it is crucial to properly design and install the right type of heat exchanger in order to maximize the run-length in-between maintenance.

Alfa Laval’s vast expertise and broad range of low-fouling heat exchangers provide you with the best solution to mitigate fouling problems at your plant.

Corrosion resistance

Desalter effluent water contains a high content of chloride salts. To minimize or eliminate corrosion problems, it is important to select the the right material for desalter heat exchangers based on the salt concentration, pH value and temperature.

Selecting a high-grade corrosion-resistant metal for traditional shell-and-tube heat exchangers is very expensive. But selecting the same metal for use in highly efficient Alfa Laval heat exchangers is much less expensive because the heat transfer surface is at least three times less than comparable shell-and-tubes and plates are made of thin metal sheets. This makes it both easy and economical to choose non-corrosive materials that extend the lifetime of critical process equipment.

CAPEX savings

To achieve high heat recovery, minimal fouling and less corrosion, it is necessary to use several large shell-and-tubes made of high-grade material in series. To ensure maximum uptime, the installation of stand-by equipment is recommended. However, this is a very costly solution – both in terms of the initial equipment investment cost and the installation costs.

Alfa Laval high-efficiency heat exchangers feature compact, space-saving designs with low fouling tendencies and are made of high-grade, corrosion-resistant material. This reduces both the size and number of heat exchangers required, thereby cutting the total installed cost of the equipment.

Proven crude oil desalting heat exchangers

Alfa Laval has about 100 heat exchangers installed in refinery desalting processes around the world. These maximize feed water preheating while effectively cooling effluent water. While doing so, our heat exchangers deliver continuous uptime and extend equipment lifetime to the crude oil refiners.