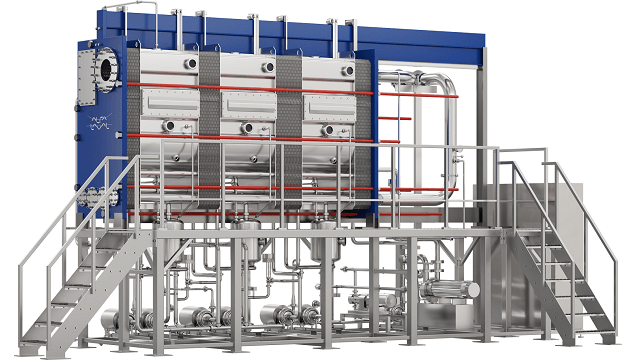

AlfaVap Inline

Efficiently concentrate heat-sensitive, low- to medium-viscosity and low- to medium-fouling products with the multi-effect Alfa Laval AlfaVap Inline. Purpose-built on a modular process skid, this ultra-compact, energy-efficient rising film plate evaporator reduces capital expenditures, operating expenses and carbon footprint while raising product quality and accelerating time to market.

Evaporation optimized for the food industry

- Ultra-compact evaporator, like no other

- Lower retention time, higher product quality

- Easy to operate

- Easy to access, minimal maintenance

- Global company with 140 years of food processing expertise and extensive local service network

Sustainably concentrate food products with the Alfa Laval AlfaVap Inline climbing film plate evaporator. It takes up less floor space, is lower in height and more lightweight than comparable evaporators. Manufactured using less steel, it requires less fuel to transport and a smaller concrete foundation for support. It fits into tight spaces or existing structures, reducing installation costs.

The AlfaVap Inline reduces retention time to minutes. It minimizes product exposure to heat by up to five times compared to falling film evaporators, resulting in higher product quality.

Typical applications include fruit juices, sugar and sweeteners, herbal extracts, and protein hydrolysates.

With the Alfa Laval plate evaporation system, we achieve better ginseng flavour- Mr. Lee Kumwoo, Production Manager at Daedong Korea Ginseng Co. Ltd.

Comparison: Falling film, traditional AlfaVap system and AlfaVap Inline

| Falling film | AlfaVap | AlfaVap Inline | |

| Length(m) | 9 | 8 | 6 |

| Width(m) | 8 | 4 | 2.5 |

| Height(m) | 15 | 6 | 4 |

| Installation time | 4 weeks | 2 weeks | 2 days |

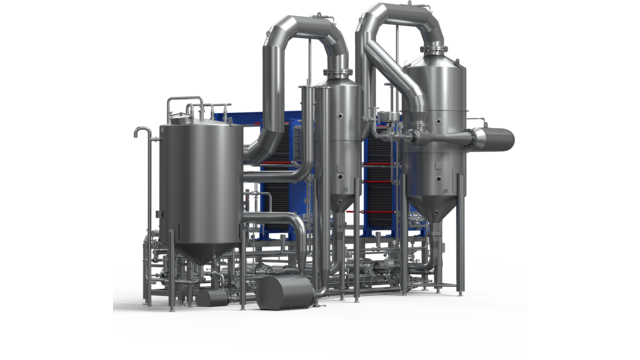

How does this plate evaporator work

The AlfaVap Inline climbing film plate evaporator optimizes process performance, producing a higher quality concentrated liquid than comparable evaporation systems. It comprises a complete module with one or more evaporator plate packs connected to a vapor-liquid separation vessel. Each evaporator consists of a plate pack. The liquid feed enters the evaporator through two inlets at the unit’s bottom. As the liquid flows over the plates in one channel, the steam in the other channel heats the plates, causing the liquid to evaporate. The heated vapour rises through the channels. The vapour-liquid mixture leaves the plate heat exchangers and enters a vapour separator, an integral part of the AlfaVap Inline module. The mixture separates into a vapour, which exits through an outlet at the top, and a liquid, which flows through an outlet at the bottom of the separator for subsequent processing in the next effect, or to the final extraction point.

AlfaVap Inline climbing film evaporator can operate with small temperature differences, allowing for an increase in the number of effects without increasing the overall temperature difference of the evaporation station, thereby reducing steam consumption and operating costs

Possible fossil free concentration process

A lot of water is transported on our roads today and by reducing the water content in food products using an evaporation system, you will reduce the energy consumption in transportation.

A concentration step is typically what would be the highest energy consumer in your whole process plant, which also makes that the process step most suitable to optimize to save energy. In in most cases, the energy for an evaporation system is coming from fossil fuels. With AlfaVap, you can transfer that over to electrical energy, making it possible to get completely fossil free energy for your concentration process.

Watch this webinar to learn more about how to produce more food and beverages, while using less water and emitting less carbon.

Nos prestations de Service

Services pour les systèmes agroalimentaires

Les services pour les systèmes de production agroalimentaire d'Alfa Laval aident à optimiser les performances de vos systèmes alimentaires en améliorant les performances des processus. Cela vous permet de :

- Améliorer continuellement vos opérations pour conserver votre avantage concurrentiel

- Vous concentrer sur le temps de fonctionnement, l'optimisation et la disponibilité

- Maximiser le retour sur investissement tout au long du cycle de vie de vos systèmes alimentaires