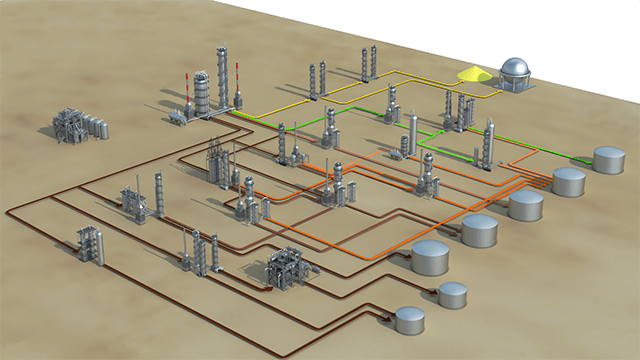

Alfa Laval process solutions for refineries

Alfa Laval can optimize all types of refinery processes. Click on the links below to learn more about some of the processes that we have helped refineries revamp. Many of these improvements are applicable to other processes in crude oil refineries and aromatic plants too. Contact us for more information about how we can help upgrade your specific processes.

Optimal process design

Hear from Alfa Laval’s Eva Andersson and Wivika Laike about how our solutions can help you increase the profitability and sustainability of your refinery.

Did you know that every year, Alfa Laval’s installed plate heat exchangers save refineries 54 TWh of energy? The corresponding reduction in CO2 emissions is over 13 million tonnes.

Crude distillation

- Increased capacity and product yield

- Substantially lower energy consumption and CO2 emissions

- Increased operating reliability

- Reduced investment cost

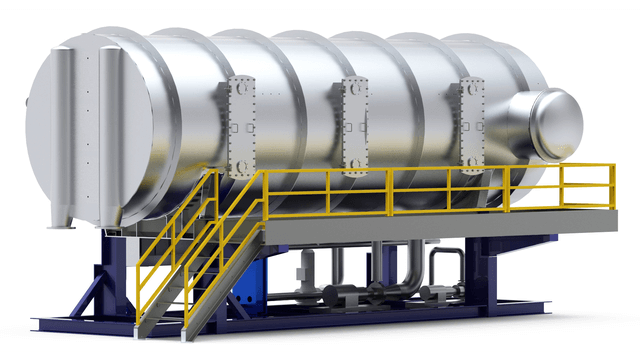

Crude oil desalting

- Improved desalter efficiency

- Maximal effluent cooling

- Reduced cleaning and repair costs

Catalytic reforming & isomerization

- Increased capacity

- Lower energy consumption

- Improved product yield and quality

- Reduced investment costs

Alkylation

- Improved reactor efficiency

- Increased product yield and quality

- Reduced investments in the refrigerant loop

Renewable fuels production

- Maximal feed stock flexibility

- Improved product yield and quality

- Minimal environmental footprint with maximal waste heat recovery and wastewater recycling

Catalytic hydrotreatment

- Increased capacity

- Lower energy consumption

- Increased cycle length and improved equipment on-stream availability

- Highest equipment reliability

Blue hydrogen production

- Increased CO2 capture efficiency

- Minimized energy and cooling water consumption

- Reduced cost in CO2 compression package

Hydrocracking

- Maximal plant conversion rate and product yield

- Reduced energy consumption

- Maximal run-length in-between heat exchanger cleanings