Visbreaking and thermal processing

Converting heavy hydrocarbon fractions into middle distillates for diesel fuels is critical to profitability. But the higher the conversion rate, the higher the residue fouling tendency, which affects energy recovery that is required to heat the process feed. Alfa Laval spiral heat exchangers maximize energy recovery, extend the intervals between cleaning, optimize conversion rates and boost yields.

Optimizing refinery visbreaking processes and thermal processing

Alfa Laval has broad expertise in optimizing refinery processes, including visbreaking and thermal processing. Our equipment and services increase energy efficiency, reduce maintenance costs, increase production and boost profitability.

Energy efficiency

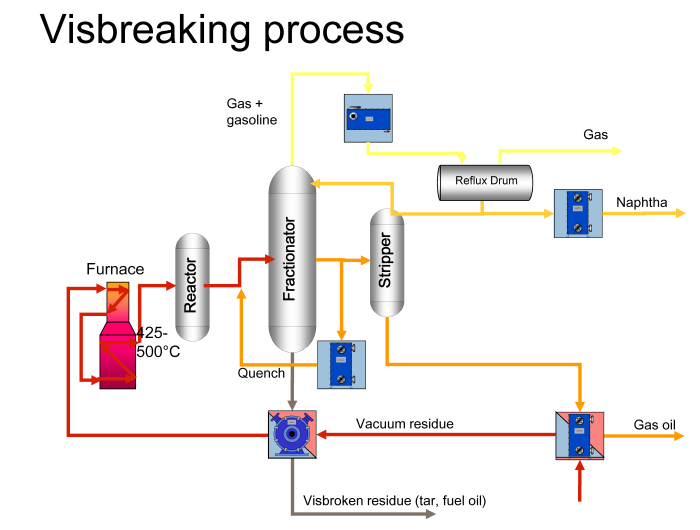

Refinery visbreaking processesare heat-intensive, requiringtemperatures of approximately 500°C. To minimize plant operating costs, it is therefore important to obtain the highest possible feed temperature into the fired heater. In some refineries, the visbreaking unit (VBU) is thermally integrated with the vacuum distillation unit (VDU), and straight-run short residue is fed directly to the fired heater. In other refineries, the visbreaking unit is a stand-alone plant, that is fed from the tank.

No matter the setup, it is critical to maximize energy recovery from the visbroken residue into either the VBU feed or the VDU feed in order to minimize the energy consumption and environmental footprint of the plant. Recovering this energy normally requires a train of several large shell-and-tube heat exchangers installed in series and in parallel. Efficiency is not very high and, due to the nature of the fluids, severe fouling further reduces performance over time. High-efficiency Alfa Laval spiral heat exchangers are tailor-made for maximizing energy recovery from high fouling media while maintaining high performance over time.

Mitigating fouling in visbreaking processes

After being subjected to high-temperature cracking, the remaining visbroken residue is very unstable. Although the media is quenched at the reactor outlet, cracking may continue and asphaltenes may continue to precipitate from the residue. The higher the conversion rate, the more unstable the residue becomes and the more severe the fouling problems in the heat exchangers. The presence of coke particles further intensifies the fouling problems.

To minimize fouling, it is important to cool the residue quickly and efficiently as well as to minimize the hold-up time in the heat exchangers. It is also important to avoid dead zones with stagnant flow, or maldistribution, which create low velocities in the heat transfer channels.

Alfa Laval spiral heat exchangers are optimal for this kind of service. With highly efficient cooling capabilities and thereby low hold-up time, these heat exchanger feature a single channel flow for perfect control of channel velocities and no dead zones, which greatly minimizes the fouling tendency. This translates into improved energy efficiency over time as well as reduced maintenance requirements.

In many cases, Alfa Laval can design our spiral heat exchangers so that there are no cleaning requirements between scheduled plant shut-downs. If cleaning is needed during regular operation, the maintenance cost and time is drastically reduced due to easy access to the heat transfer channels for mechanical cleaning.

Increasing capacity

There are three ways to increase capacity of refinery visbreaking processes: (1) increasing plant throughput, (2) increasing plant conversion rate, and (3) increasing plant availability.

Increasing plant throughput

Capacity in visbreaking units is often limited hydraulically; in other words, when fouling occurs, there is a build up in pressure drop and, at some point, the hydraulic limitation of the pump is reached and throughout must be reduced. In same way, fouling in heat exchangers will also reduce the efficiency of heat recovery and eventually, the capacity limit of the furnace may be reached.

Low-fouling Alfa Laval spiral heat exchangers minimize fouling thereby maximizing throughput over the cycle length. With additional heat recovery, it may even be possible to creep the plant capacity without requiring any modification to the fired heater.

Increasing plant conversion rate

Capacity increase can be achieved not only by increasing the throughput, but also by increasing the conversion rate of the plant. However, because an increased conversion rate means increased fouling, there is a limit as to how high a conversion rate can be used while operations remain economically feasible. With low-fouling Alfa Laval spiral heat exchangers the conversion rate can be significantly increased while ensuring minimum fouling tendency. This translates into higher yields of valuable products while producing less residue.

Increasing plant availability

Another way of increasing plant productivity is to increase plant availability. Most visbreaking units only operate between six and nine months before the plant needs to be shut down for maintenance. Most of the time, the decisive factor for plant shutdown is due to the need to de-coke the fired heater tubes. Coking of those tubes occurs because of the high heat flux required for the final preheating of the feed.

With high-efficiency Alfa Laval spiral heat exchangers, it is possible to recover more energy from the residue and thereby preheat the feed to a higher temperature before the feed enters the fired heater. This reduces the heat flux in the heater as well as the coking of the heater tubes. Reduced coking extends the operating intervals to up to 24 months before the plant needs to be shut down for maintenance. This raises plant availability and increasing productivity.

CAPEX savings in visbreaking processes

Recovering the energy from visbroken residue and other hot fractions normally requires several large, bulky traditional shell-and-tube heat exchangers. Moreover, redundant units are required when equipment is being cleaned. Using high-efficiency Alfa Laval spiral heat exchangers, on the other hand, makes it possible to reduce the heat transfer area required for a certain service. Moreover, the number of exchangers and their size and weight is reduced, thereby cutting installation costs. And because Alfa Laval spiral heat exchangers are designed to minimize fouling tendency, there is also no need to invest in spare equipment.

Proven technology for refinery visbreaking

Alfa Laval has more than 50 exchangers installed in visbreaking plants. Most are spiral heat exchangers used to recover energy from visbroken residue used to preheat either the VBU or VDU feed. One major oil company has standardized on the use of Alfa Laval spiral heat exchangers for all their visbreaking plants.