Energy efficiency

Energy efficiency is one of the main contributors to reaching the Paris Agreement. By optimizing the world’s energy consumption, and being able to produce more from less, we can meet our increased energy demand and reduce CO2 emissions at the same time. In fact, according to the International Energy Agency, increased efficiency could account for more than 40% of emissions reductions in the next 20 years.

As much as 50% of today’s potential for energy efficiency saving comes from the industrial sector, and 30% can be achieved in buildings. And the solutions to enable these energy efficiency improvements already exist! At Alfa Laval, we have spent decades developing plate heat exchanger technologies that help businesses optimize energy use in their processes. Our products are used in everything from the heavy process industries to data centers, domestic heating and cooling, and much more. Our unique thermal solutions make it possible to save dramatic amounts of energy and thereby reduce carbon emissions – no matter the application!

A partnership to accelerate your sustainability

Every kW of energy saved is just as valuable as producing one new kW of clean energy. At Alfa Laval we know how to make your processes more efficient – and more sustainable. For more than 90 years, we have developed plate heat exchangers to optimize thermal transfer in heating and cooling duties.

In this video you can learn how our innovative solutions are already supporting customers’ increased need for energy efficiency and emission reduction.

Making energy efficiency a win-win for you

Meet Julien Gennetier, VP of the Energy Division here at Alfa Laval and one of the foremost industry experts on the subject of energy efficiency. In this video, Julien explains how saving energy will not only make a big difference when it comes to helping our planet. It’s also a smart way to reduce costs and boost your profitability. In other words: a win-win!

A pioneering partnership from two sustainability leaders

Alfa Laval and Stena Recycling have teamed up create a smart, sustainable and easy-to-use solution for improving circularity in our industry. Called Re-Made to matter, this new exchange programme will make it possible to recover as much as 100% of the valuable metals found in old heat exchangers. By replacing them with more modern designs, we can also enable efficiency improvements for energy savings as well as a reduced carbon footprint.

Watt’s it worth?

Did you know that plate heat exchangers are up to 50% more efficient than traditional technologies, like shell-and-tube heat exchangers?

Every year, newly installed Alfa Laval plate heat exchangers make it possible for our customers to reduce their capacity needs by 50 GW. That is enough power to heat 10 million homes in Europe for one year.

In carbon emissions, 50GW translates to a 25 million tonne reduction to our global footprint or the annual carbon emitted by Paris.

Imagine what we could do if all industries used plate heat exchangers instead of traditional technologies to maximize heat transfer efficiency.

Curious what it can mean for your processes? Contact us today, and our experts will be in touch!

See all the numbers

Alfa Laval sustainability experts work closely with partners all around the world, in virtually every industry imaginable. How much can we minimize energy consumption in refineries? What about the reduced carbon footprint for data centers? Or are you curious to see the energy savings in the chemical sector or in buildings and construction?

We have detailed data on the energy and emissions reductions that Alfa Laval plate heat exchanger technologies enable across a broad spectrum of industries. Click here to get access to these and many more!

Emission reduction

Rolling back carbon emissions from where we are today is the greatest problem of our time. Such a complex challenge can’t be solved by a simple solution. In fact, a large range of solutions will be needed.

In addition to plate heat exchangers that enable higher efficiency for reduced energy consumption, Alfa Laval’s proven heat transfer and separation technologies are helping customers in a variety of industries to reduce emissions in a variety of ways.

Click here to learn how we’re helping to accelerate new solutions for carbon capture, natural and low-GWP refrigerants and much more.

Waste heat recovery

What happens to the heat that your processes generate? If you’re just letting it escape into the surrounding atmosphere, you’re missing out on one of the most effective ways to improve the energy efficiency of your operations.

With the right heat exchanger technology, you can recover high temperature heat generated by industrial processes, as well as lower temperature heat captured by heat pumps in, for example, data center cooling or water treatment applications. This heat can then be used for applications ranging from district heating to producing electricity.

Click here to learn more about Alfa Laval’s extensive expertise in this area, and how we can help you.

Presence in a wide range of industries

Alfa Laval’s efficient plate heat exchangers are used to save energy and reduce emissions in industrial processes, all across the world. Today we are present in everything from the heavy process industries to data centers, HVAC and much, much more. Select your industry below to learn more.

HVAC

Did you know that heat pumps are four times more efficient than traditional boilers in residential heating and cooling?

Each year, heat pumps based on Alfa Laval’s plate heat exchangers save up to 29 TWh of electricity, which reduces carbon emissions by 6.6 million tonnes.

The electricity saved is the same amount required to heat 2.7 million Chinese homes.

How much can you save in your HVAC operation?

Refrigeration

Imagine if all new cooling installations in refrigeration plants used Alfa Laval compact plate heat exchangers instead of traditional technology. That would save 628 GWh of electrical power and reduce CO2 emissions by 144,000 tons – every year!

The energy saving is equivalent to that needed to cool 290,000 homes in Singapore. And the emission reduction corresponds to the emissions produced by 470 flights from London to Shanghai.

What can we do for your refrigeration systems?

Data center cooling

Imagine if all data centers installed plate heat exchangers to enable free cooling by 2030. It could save 30 TWh in electrical power – the equivalent to the electricity consumed annually in all of New Zealand! It would also reduce CO2 emissions by 7 million tonnes, or what is produced every year by the whole city of Boston.

More efficient cooling operations with Alfa Laval plate heat exchangers can make this possible.

Curious about what we can do for your data center?

Crude oil refineries

Did you know that refining represents 6-8% of all industrial energy use?

Just imagine if all refineries switched from traditional technology to Alfa Laval’s efficient plate heat exchangers. This would reduce global energy consumption by 23%. And the corresponding reduction of 245 million tons of CO2 would be equivalent to the annual emissions of Spain!

Find out more by reading our full story.

Petrochemicals

Did you know that an Alfa Laval plate heat exchanger transfers heat up to 5 times more efficiently than traditional shell-and-tube technology?

If all petrochemical plants used more efficient Alfa Laval plate heat exchangers, we could reduce energy consumption by 132 TWh annually, eliminating 28 million tonnes of CO2 from our atmosphere! This is equivalent to the emissions from the city of Qingdao.

Are you curious about how we can help you make your processes more sustainable?

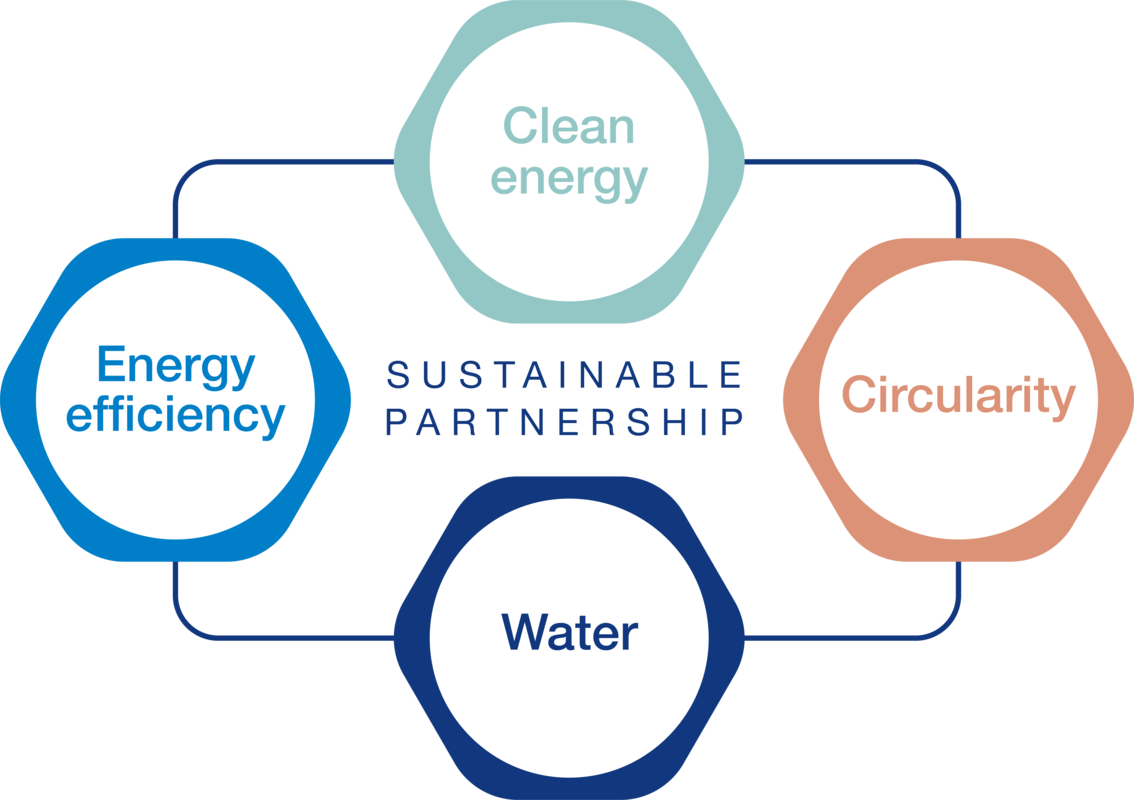

Energy efficiency

Clean energy

Sustainable partnership

Contact us to learn more

Contact us today for more information about our sustainable solutions