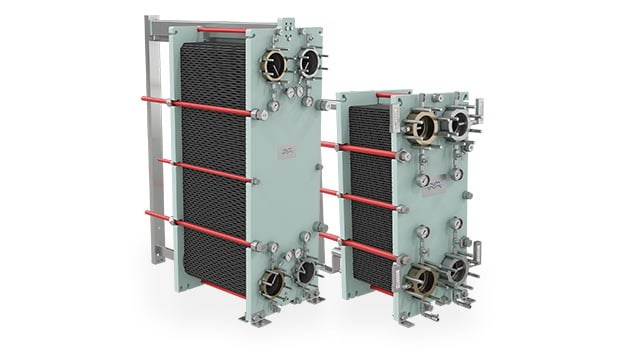

Marine gasketed plate heat exchangers

Alfa Laval has been developing heat transfer technology for more than 80 years and has been active in the marine industry for over a century. Based on that vast wealth of experience, our engineers have designed gasketed plate heat exchangers that set entirely new standards – not only for reliability, but also for thermal performance and ease of service.

The marine industry’s most modern line of plate heat exchangers

- Superior reliability and energy efficiency

- Small size and footprint (CompactFrame™ design)

- Minimal fouling (CurveFlow™ plate distribution area)

- Easy installation and service (five-point alignment system)

- Optimized global supply chain and production for smallest environmental footprint

Suitable for any vessel, Alfa Laval gasketed plate heat exchangers excel in applications from general heating and cooling to heat recovery, condensation and evaporation. With their innovative features, they take reliability to an all-new level and save crews time and effort during maintenance. Above all, their design minimizes fouling and maximizes heat transfer capabilities, which ensures the highest possible energy efficiency.

Key products

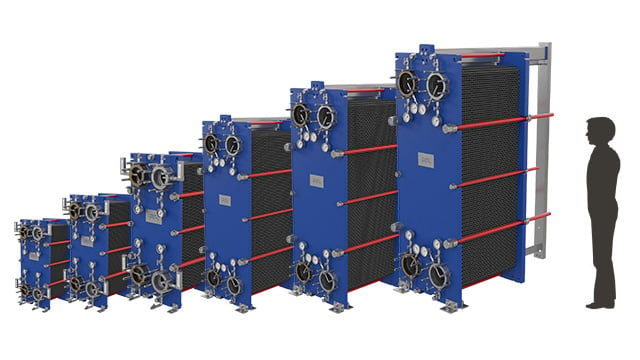

Gasketed plate heat exchangers for your vessel

Compact, reliable and energy-efficient, Alfa Laval gasketed plate heat exchangers are also safe and simple for crews to maintain. Our flexible marine line provides the right match for your needs today – with the possibility to adjust capacities later.

| T6 DN 60 |

T10 DN 100 |

T15 DN 150 |

T21 DN 200 |

T25 DN 250 |

T35 DN 350 |

|

|---|---|---|---|---|---|---|

| H (mm) | 890 | 1054 | 1833/1781 | 2082 | 2761 | 2875 |

| W (mm) | 320 | 470 | 610/650 | 755 | 913 | 1174 |

| Max flow rate (m3/h) | 60 | 160 | 370 | 650 | 1000 | 1970 |

| Capacity (kW) – water duty with LMTD 6 | 800 | 3 000 | 9 000 | 18 000 | 28 000 | 35 000 |

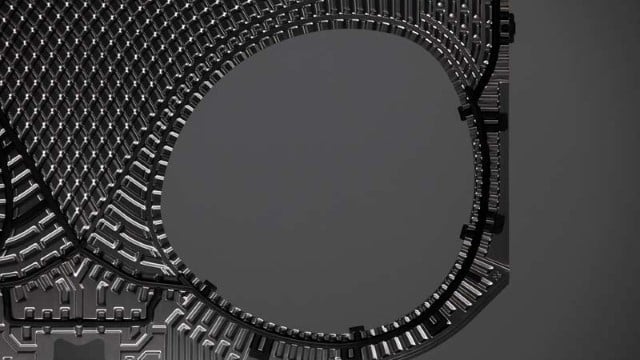

How it works

The heat transfer area of a gasketed plate heat exchanger consists of a series of corrugated plates, assembled between a frame and pressure plates to retain pressure. Gaskets act as seals between the plates. Fluids normally run counter-currently through the heat exchanger. This gives the most efficient thermal performance and enables a very close temperature approach, ie the temperature difference between the exiting process medium and the entering service medium.

Alfa Laval liquid/liquid gasketed plate-and-frame heat exchanger

Features that make the difference

The Industrial line is equipped with features that turn this high-performance family into efficient and reliable workhorses that are easy to service and maintain over the whole product lifecycle.

For efficiency

By improving the efficiency of your heat exchanger, you can maximize production and minimize energy consumption to reduce your power bill and improve your environmental footprint.

See product animations below or get more information and listen to our technical experts.

CurveFlow™

CurveFlow™

distribution area

Improves media flow and minimizes risk of fouling.

OmegaPort™

OmegaPort™

noncircular port holes

Enhances media flow and thermal efficiency.

FlexFlow™

FlexFlow™

plate design

Improves thermal efficiency and optimizes pressure drop utilization.

For reliability

We are always looking to increase the reliability of every aspect of our gasketed plate heat exchangers.

We focus on durable designs based on robust materials and safe manufacturing processes.

See product animations below or get more information and listen to our technical experts.

PowerArc™

PowerArc™

plate pattern divider

Improves plate rigidity for longer lifetime.

Five-point alignment

Five-point alignment

Ensures reliable plate positioning and easy to service for large units.

SteerLock™

SteerLock™

plate alignment

Ensures reliable plate positioning and easy service.

For serviceability

The simple opening and closing of the plate-and-frame design with gaskets enables hassle-free inspection and service. It also enables you to easily adapt the unit to new process conditions.

See product animations below or get more information and listen to our technical experts.

ClipGrip™

ClipGrip™

gasket attachment

Ensures perfect seal and trouble-free maintenance.

T-bar roller

T-bar roller

Provides a lower unit that is easy to service.

Bearing boxes

Bearing boxes

Guarantees an easy-to-open unit for smoother, more efficient maintenance.

Compact frame

Compact frame

Facilitates maintenance and minimizes service area requirement.

Services

Marine service network

Our dedicated Marine Service Network supports you with parts and expertise, wherever you are, whenever you need it. By ensuring greater uptime, availability and optimization, we help bring you peace of mind, and maximize your return on investment.

24/7 Service & Support

Contact us anywhere, anytime:

+46 4636 7700

marine.service@alfalaval.com

Our global network of service centres, distribution centres and field service engineers is always ready at assist you.

Documents

Downloads

Instructions and manuals

Product brochures

Heating and cooling in an engine room

On a ship, there are many types of machinery with a cooling demand. When the heat energy cannot be recovered or utilized, the total costs of transferring it away from the machinery should be kept to a minimum. Alfa Laval can ensure a cost-effective central cooling system through our portfolio of innovative plate heat exchangers. Our gasketed plate heat exchangers have unique features that reduce the running costs for engine room cooling – and contribute to sustainability.

Are you on a quest to save energy?

Alfa Laval is setting the standard for thermal efficiency of plate heat exchangers. Bringing together innovative features improving energy efficiency and minimizing downtime we can accelerate the transition to more sustainable solutions and reach net-zero by 2050.

Alfa Laval technology powers sustainable operations on Maersk’s pioneering methanol-fuelled container vessel

In a world where sustainability is increasingly important, A.P. Moller-Maersk has set sail with the world’s first methanol fuelled container vessel. Equipped with Alfa Laval’s solutions for methanol as fuel, this vessel shows how innovative solutions and equipment can help shipping companies adapt to the evolving energy landscape and environmental regulations.

Demand new standards

Introducing the world’s most modern gasketed plate heat exchangers. Discover how our next-generation line of gasketed plate heat exchangers will bring you higher efficiency, better reliability and greater serviceability.