LeviMag

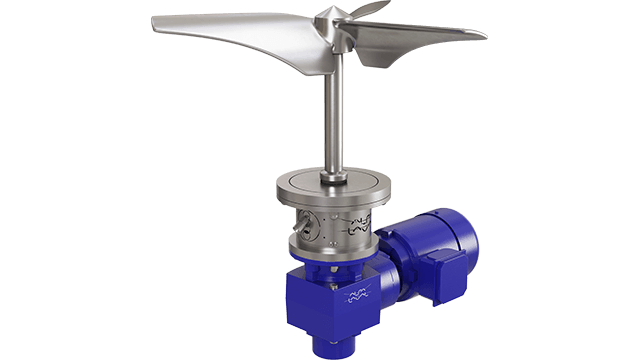

The Alfa Laval LeviMag® is an aseptic magnetic mixer that uses a patented levitating impeller and advanced design to mix down to the last drop and maximize product yield. Compact, energy-efficient and easy to maintain, it is perfect for dairy, food, beverage and other applications that have demanding requirements for hygienic production.

Maximize process economy, minimize product loss

- Optimized flow with higher efficiency and less energy consumption

- Mixing down to the last drop for maximum yield due to low agitation and dry-running capability

- Optimized Cleaning-in-Place thanks to full drainability

- Minimized downtime due to ease of maintenance

LeviMag® magnetic mixer technology

Mix down to the last drop thanks to the four-wing levitating impeller of the Alfa Laval LeviMag magnetic mixer. Minimizing wear and ensuring drainability is easy due to no direct contact between the bearing surfaces and no dead zones.

Service

Get more uptime thanks to low-wear bearings that are easy to maintain and easy for operators to replace on-site. No glue or shrink-fit is required. This minimizes downtime. Plus, there is no need for spare impellers. Tools for easy maintenance are also available.

Product models

The Alfa Laval LeviMag magnetic mixer is available in four sizes with mixing speeds ranging from 10 to 600 rpm, as the mixer’s levitating impeller design eliminates friction. This provides greater process flexibility to handle a wide range of fluid types and mixing duties, such as high-intensity and gentle product mixing.

How it works

How does the LeviMag magnetic agitator work

A radial turbine installed inside the tank is rotated via the torque from a magnetic coupling. This creates a mixing of the fluid inside the tank. The patented levitated design of the impeller makes the mixer fully drainable and able to run dry – hence it can mix to the last drop, securing maximum yield.

The unique design of the Alfa Laval magnetic coupling always ensures the levitation of the impeller. This enables the complete drainability of process fluids and the free flow of CIP liquid and steam around all parts of the mixer, ensuring a thorough cleaning. Impeller levitation also eliminates axial wear.

360° Service and maintenance videos

How to replace the female bearing and assemble

How to disassemble and replace the male bearing

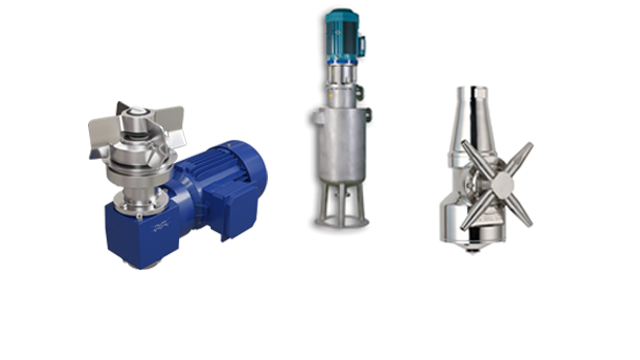

Part of a broad mixing range

Alfa Laval offers a comprehensive range of mixing equipment intended for hygienic applications in the dairy, food, beverage,home care, personal care, biotechnology and pharmaceuticals.

- Alfa Laval Hybrid Powder Mixer

- Alfa Laval LeviMag® UltraPure Magnetic Mixer

- Alfa Laval LeviMag® Magnetic Mixer

- Alfa Laval Rotary Jet Mixer

For a broader mixing range, explorer the different product categories: Agitators and mixers.

You might also be interested in ...

ALB

Our bottom-mounted agitator ALB offers mixing solutions to meet any requirements in food, dairy, beverage, pharmaceutical, biotechnology and cosmetic applications.

Sani

Engineered for hygienic applications, Toftejorg Rotary spray head tank cleaning devices offer exceptional cleanability and drainability and easy, cost-effective maintenance.

Beam load cells

Ideal for mixing, dosing or batch tasks in small or mobile tank sizes up to 4000kg

Ten top tips - Tank Equipment

Here are some tips and service videos to show you how you can keep your tank equipment in tip top condition.

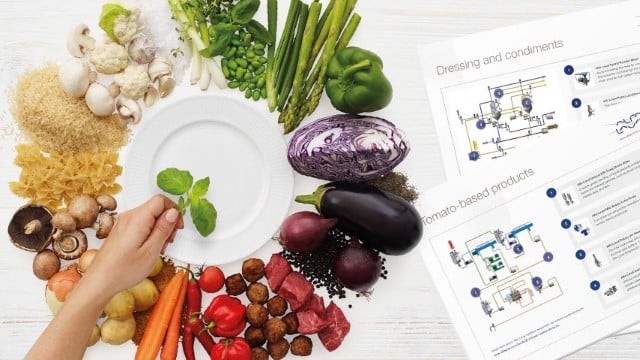

Food Logic

Alfa Laval's hygienic equipment combines high performance with gentle handling to preserve sensitive ingredients and keep up with the food industry trends. The equipment addresses four key challenges; supplying food products to consumers at a competitive price, getting the most from raw materials, reducing waste and emissions, and delivering safe and hygienic food products.

CAD portal

Download the product models in Neutral or Native CAD file formats. It is also possible to download 3D PDF files.

Animations

Visit the animations site and take a look inside a product to see and understand how it works.

Tank equipment

near Newsletter

To keep you updated on important sustainability issues and opportunities in your industry and processes.