Degumming systems

Get tastier edible oils and longer shelf life with our degumming process system that remove hydratable and non-hydratable gums —phospholipids, proteins, carbohydrates, nitrogen compounds, chlorides (precursors of 3-MCPD), metals and insoluble impurities — from all types of fats and oils. With Alfa Laval oil pretreatment: special degumming, acid degumming, enzymatic degumming and water degumming, you can easily separate gums from edible oils, minimize product loss and maximize quality and yield.

Optimize your degumming processes

- Maximize edible oil quality, shelf life and yield

- Minimize gum content and further operating costs in oil refinery

- Reduce loss of neutral oil and utility costs

- Raise operational reliability and efficiency; boost uptime and service life

- Minimize 3-MCPD precursors

Alfa Laval is not only a supplier to us but also a partner, guide and friend” - Valeriy Fedorenkov, Technical Director, Odessa Maslozhircombinat

Due to this innovative step, we’ve seen a significant increase in oil yields and processing margins, enabling our facility to exploit its potential even better,” - Luis Palacios, Molinos’ Industrial Manager of Molinos Río de la Plata

Versatile degumming systems for edible oil refining

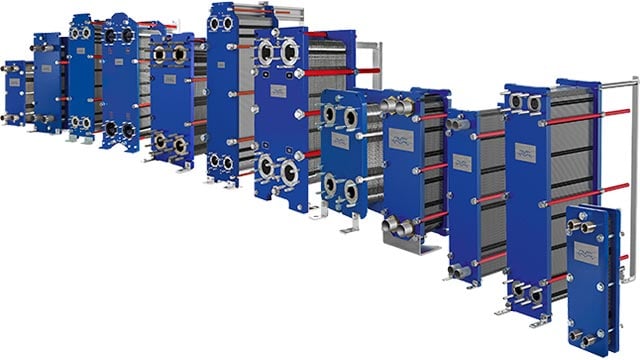

Get the flexibility you need to ensure highly reliable and cost-effective refinement of your edible oils. Choose from Alfa Laval’s broad degumming system portfolio, including high-efficiency disc stack centrifuges, plate heat exchangers and mixers. Modular and easy to install, use and maintain, all equipment can be integrated into existing pre-treatment process lines as stand-alone items or designed and optimized as a complete system.

Water degumming

For removal of hydratable gums using Alfa Laval mixers and disc stack centrifuges. Dried gums can be used for lecithin production which are valuable food additives.

Enzymatic degumming

For removal of hydratable and non-hydratable gums, chlorides (precursors of 3-MCPD formation at downstream refining processes) using Alfa Laval disc stack centrifuges and heat exchangers.

Special degumming

For removal of hydratable and non-hydratable gums using acids or a combination of acids and caustic soda and Alfa Laval’s self-cleaning disc stack centrifuges with a special CentrizoomTM paring disc.

Acid degumming

For removal of gum-like impurities and metals from animal fat using Alfa Laval disc stack centrifuges.

How it works

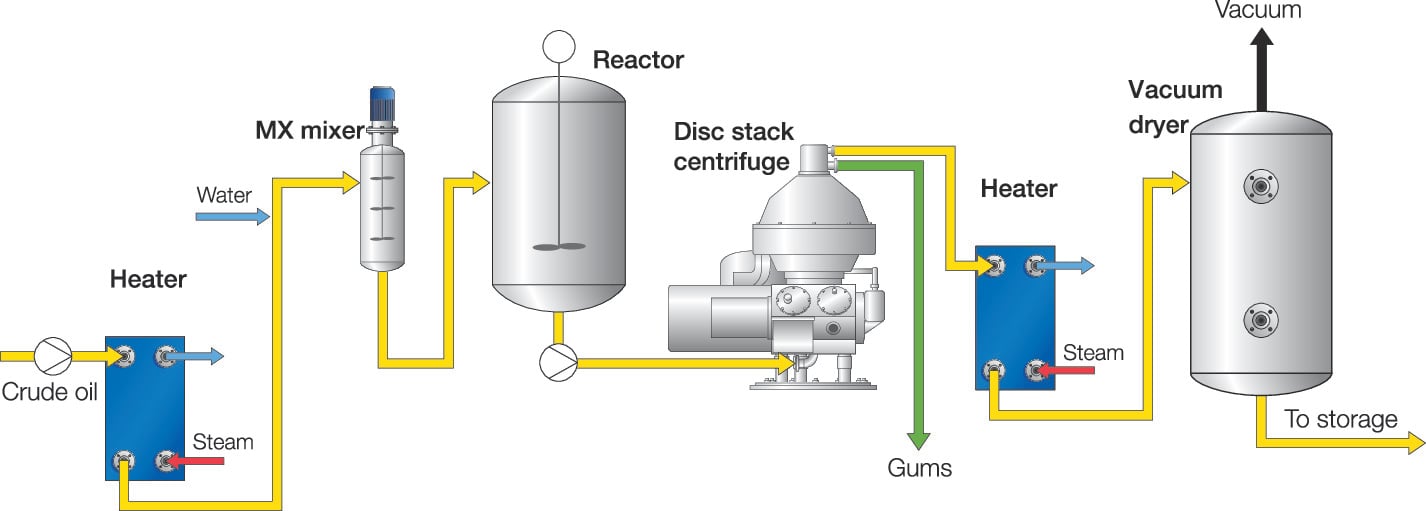

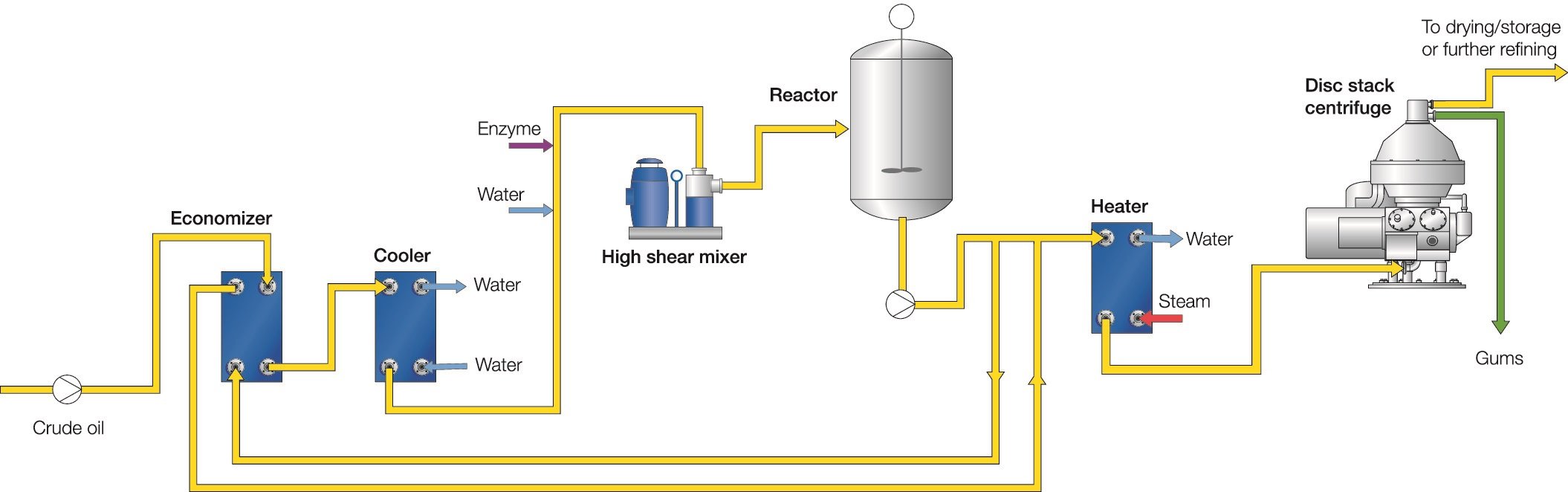

Water degumming

This relatively simple, cost-effective process removes as much gum as possible in the pre-treatment stage. Gums removed here are generally dried to form lecithin, a valuable by-product; however, if preferred, the gums may instead be returned to the meal in the extraction plant.

Effective degumming means that less material needs to be removed downstream during neutralization. It also means there is less soapstock produced that require further treatment or disposal.

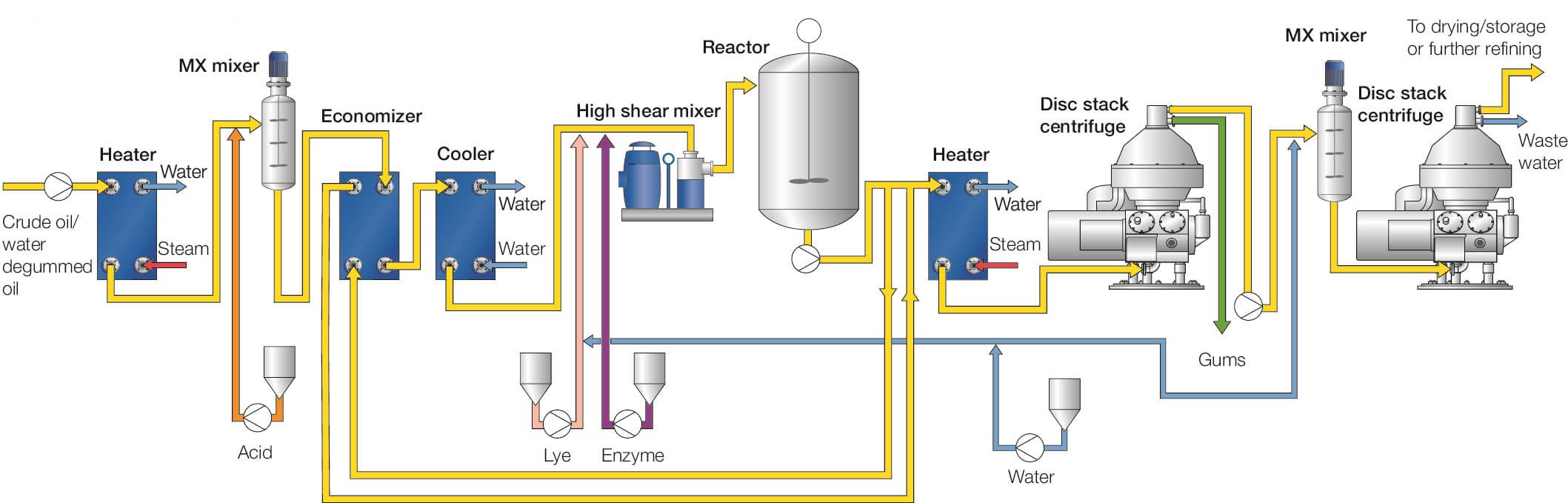

Enzymatic water degumming

To degum oils with high and very high phospholipid content, Alfa Laval recommends enzymatic water degumming. Here the phospholipase C enzyme (PLC) breaks down phospholipids into diacylglycerol (DAG) and a water-soluble, phosphate-bearing ester fragment, which reduces gum content, minimizes oil loss and increases neutral oil yield.

Enzymatic deep degumming

Pre-treatment of seed oils with a small amount of acid effectively removes gums to a sufficiently low level to enable further processing. The addition of diluted lye enables adjustment of the pH value prior to dosing an appropriate enzyme. The phospholipase A enzyme (PLA) converts both hydratable and nonhydratable gums into lyso-gums and free fatty acids. The lyso-gums are more hydrophilic, which makes them easier to remove from the oil during centrifugation. Moreover, enzymatic deep degumming significantly reduces the presence of chlorinated compounds, which contribute to the formation of 3-MCPD if not removed.

Acid degumming

By intensive mixing of a small amount of a citric acid and water at controlled temperatures, this animal fat refinement process enables the separation of gums, gum-like impurities and metals from selected animal fat.

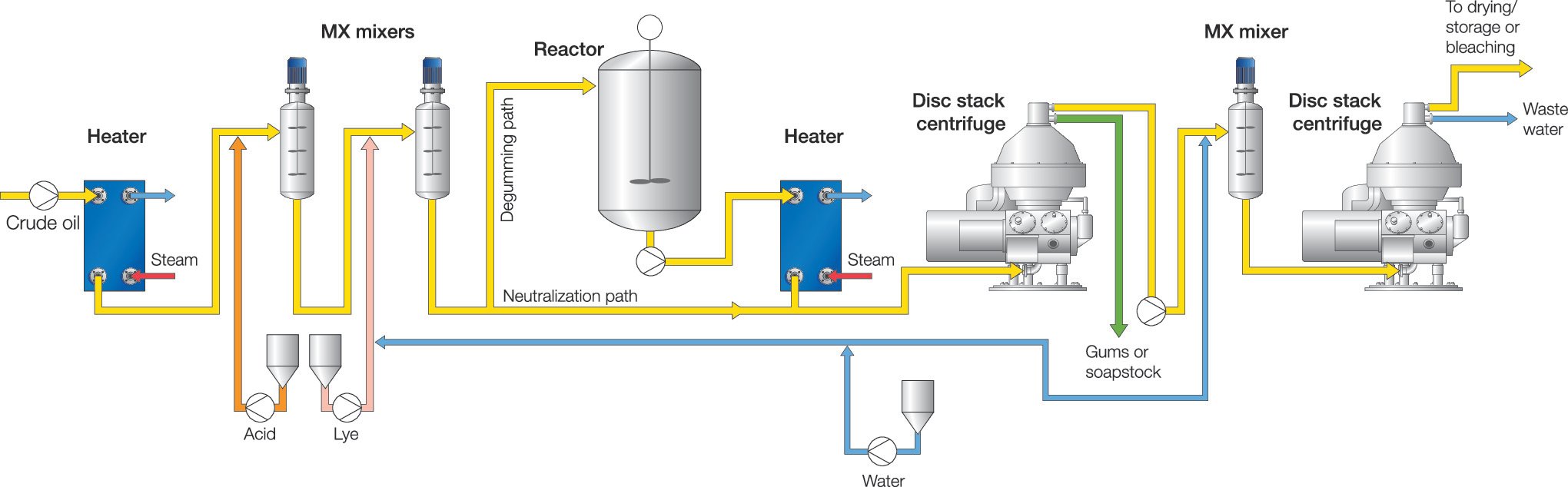

Special degumming

Through the addition of a small amount of a suitable acid and diluted lye at carefully controlled temperatures, this physical seed oil refinement process enables the separation of both hydratable and nonhydratable gums from selected oils. The gums removed are highly viscous; however, Alfa Laval self-cleaning disc stack centrifuges equipped with special CentrizoomTM paring disc outlets easily handle the task. The resulting oil quality makes further processing possible, except in the case of low-quality seed oils. To maintain the quality of the final product, these oils may require the full caustic neutralization to remove free fatty acids and residual gums or the Combi Mix process (see below).

Combi Mix process

This two-stage process provides the flexibility you need to process good quality seed oils that require physical refining as well as any lower-quality oils for which neutralization using caustic soda is the only viable way to remove impurities.

Choose from Alfa Laval’s comprehensive degumming systems, including special degumming, acid degumming, enzymatic degumming, and water degumming. Plus get expert advice on the system that best suits for your requirements.

What better way to minimize product loss and maximize the quality and yield of your edible oils? Whether phospholipids, proteins, carbohydrates, nitrogen compounds, chlorides (precursors of 3-MCPD), metals and insoluble impurities, you can be sure the Alfa Laval degumming process selected is up to the task.

Customer's voice

Aïcha

Aïcha is the leading producer of marmalade, olive oils and tomato paste in Morocco. The company operates a refinery that uses 100% Alfa Laval equipment, including a SoftColumn deodorizing plant, disc stack centrifuges and heat transfer equipment.

It’s not an exaggeration to say this is the most sophisticated edible oil refinery in the country. We are at least 10 years ahead of our Moroccan competitors.”

- David Devico, managing director.

Odessa Maslozhircombinat

Odessa Maslozhircombinat (fats and oils plant in Odessa) is one of the leading producers of margarine, mayonnaise and bottled sunflower oil in Ukraine, with operations that include a sunflower oil refinery.

When the company ran into quality problems with its existing degumming process, it turned to Alfa Laval for assistance. The outcome was the installation of an Alfa Laval special degumming process line that helped the plant produce oil of a better quality, while also enabling it to reduce losses.

Alfa Laval is not only a supplier to us but also a partner, guide and friend”

- Valeriy Fedorenkov, Technical Director.

Molinos Río de la Plata

Molinos Río de la Plata, Argentina’s leading soybean and sunflower seed processor, selected Alfa Laval to convert its San Lorenzo facility to the Purifine PLC degumming process.

Due to this innovative step, we’ve seen a significant increase in oil yields and processing margins, enabling our facility to exploit its potential even better

- Luis Palacios, Molinos’ Industrial Manager.

Webinars for the Edible Oil industry

Our experts share know-how to optimize edible oil refining processes, remove impurities and volatile components for better product quality, safety and yield.

Optimizing edible oil process system performance

More than 130 years of experience. Experts the world over. Service centres in nearly 100 countries. Take advantage of the Alfa Laval global service network with local service centres and partners in worldwide. No other process system supplier can provide the depth, breadth and range of components, equipment, systems and service. We take care of your degumming system, so you get the most out of it.

Discover how fine-tuning your degumming systems can raise your edible oil productivity and profitability. Download the Alfa Laval degumming and neutralization solutions brochure or talk to us.