Optimizing every dairy process

Alfa Laval’s comprehensive range of innovative hygienic components are key building blocks in dairy processes. The processes highlighted on these pages are important to dairy applications.

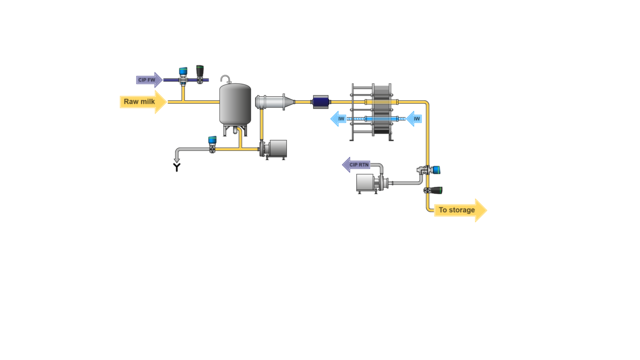

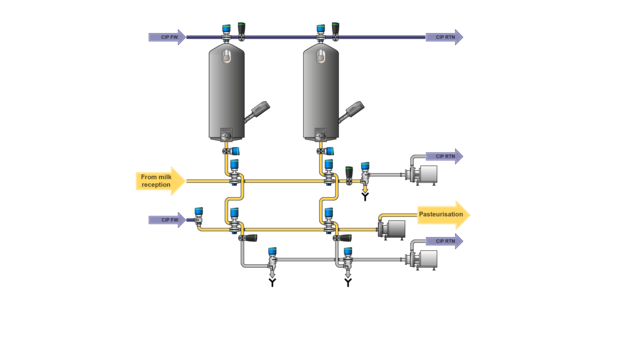

Milk Reception

Milk reception and storage demand uptime and efficiency. That means components with high reliability, easy serviceability, and both operational and energy efficiency.

Milk Storage

Increasing productivity while providing gentle raw milk handling is key during milk storage. Our hygienic components can ensure optimal and reliable fluid handling that can result in substantial savings and efficiency gains.

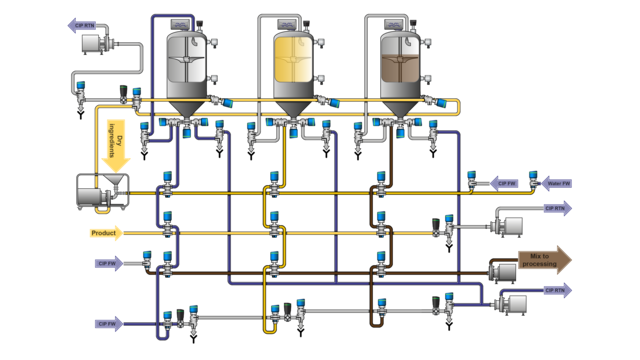

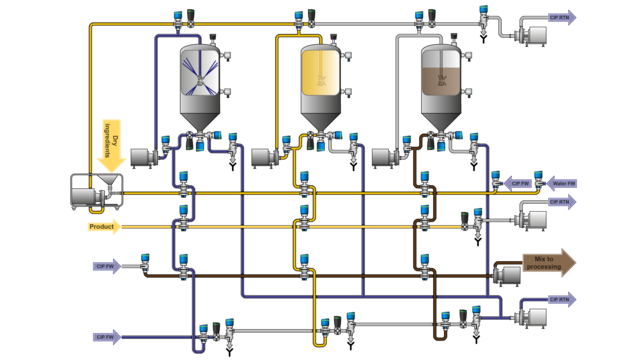

Mixing and Blending (Agitator)

Precise and uniform mixing and blending is essential in many applications, contributing to an effective process and a high-quality end product. Optimal results demand a balance between power, control and flexibility. Using an Alfa Laval Agitator with specially developed EnSaFerm impellers for fermentation use, reduce energy consumption and the absorption of heat by your product.

Mixing and Blending Rotary Jet Mixers

Precise and uniform mixing and blending is essential in many applications, contributing to an effective process and a high-quality end product. Optimal results demand a balance between power, control and flexibility. Using The Alfa Laval Rotary Jet Mixer radically increases efficiency in applications such as flavoured, fortified, and recombined milk, whipped cream based on vegetable oil, dairy powders and emulsifiers.

Pasteurization

Pasteurization processes demand high levels of safety, hygiene and process control. Pasteurization of milk is a vital process, and compliance to relevant regulations and standards is essential. Following UHT treatment, aseptic conditions must be maintained. The quality of components is key, with good flow control and reliable and efficient heat exchangers playing an important role

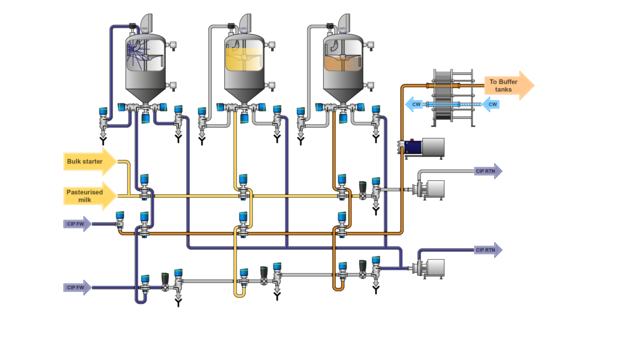

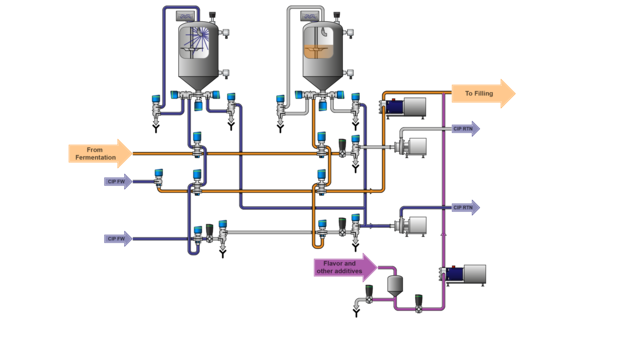

Fermentation

Getting the most from raw materials is essential in the production of cultured products and fresh and cured cheeses. Important issues include achieving maximum efficiency in continuous batching, and maintaining hygienic processing conditions

Buffer Storage

Alfa Laval's comprehensive range of innovative hygienic components are key building blocks in dairy processes. During buffer storage tank optimization is key. Our ongoing mission is to secure hygienic conditions and optimize your dairy production.

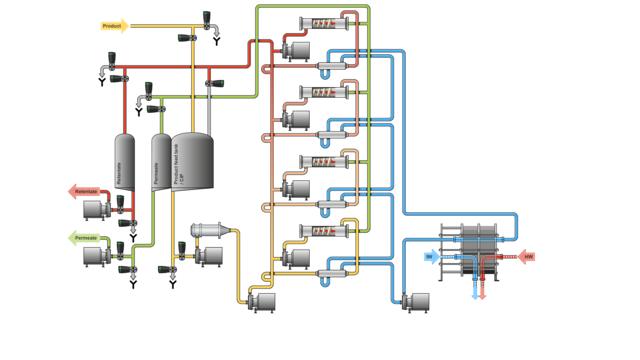

Separation

Our ultrafiltration, nanofiltration, and reverse osmosis membranes give excellent yields in pre-concentration and protein purification prior to evaporation and drying.

Concentration

Reducing waste and emissions is an essential aspect of concentration processes. Achieving a good operating economy requires control over components’ energy consumption.

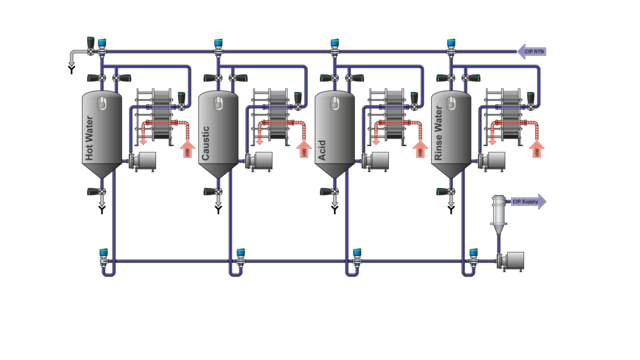

Cleaning-in-Place

Quality in CIP is essential in the dairy industry. Efficiency is the key, both in terms of cleaning results and economy. CIP economy is dictated by cost and time. Reducing waste is critical; correctly configured and efficient cleaning, pumping and heating equipment is needed to get the cleaning fluid properly out to work on the surfaces.