OceanGlide

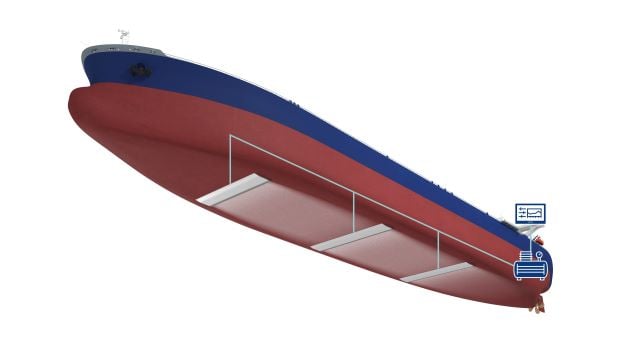

Alfa Laval OceanGlide is a unique air lubrication solution with fluidic technology. It creates an even and controllable air layer across the entire flat bottom of the vessel, which is the best setup for reducing friction between the hull and the water. The proven reduction in drag means greater energy efficiency, lower fuel costs and less CO2 emitted into the atmosphere. Along with reduced marine noise, these factors make OceanGlide an important step towards more sustainable shipping.

A smooth path to real energy savings

- Fuel savings of up to 12% mean reduced CO2 and improved EEDI, EEXI and CII

- Fluidic technology uses few compressors to produce an even and dynamic air layer

- Coverage of the entire flat bottom area maximizes drag reduction

- Individually controllable sections allow full optimization of the air layer

- Easy installation, even as a retrofit – no large sea chests, minimal penetrations and free compressor placement

Alfa Laval OceanGlide is a patented, next-generation solution that truly delivers on air lubrication’s promise. By combining air lubrication with fluidic technology, it creates an even air layer with high efficiency and little compressor power. The dynamic air layer, which covers the vessel’s entire flat bottom, can be controlled and optimized thanks to air distribution bands that divide it into sections.

OceanGlide’s innovative setup makes it easy to install on any vessel – new or existing. There are no sea chests, no compressor placement requirements and only minimal hull penetrations. This means that all vessels can benefit from 50–75% reduction in specific drag. The results are proven, reliable fuel savings of up to 12% and a substantial impact on EEDI, EEXI and CII.

Documents

How fluidic air lubrication works

Alfa Laval OceanGlide is unique in combining air lubrication with fluidics – the control of fluid pressure and flow by means of precisely shaped channels, without any moving parts. This patented integration means OceanGlide needs no sea chests or large hull penetrations, and it produces the air layer with unmatched efficiency.

OceanGlide divides the vessel’s flat bottom into sections, each with its own air distribution band. At the rear of each band is a row of fluidic oscillators, which are the individual air distribution units. Using fluidics, the oscillators release air evenly and with very little compressor power. This results in a thin and homogenous air layer.

Air distribution bands offer the best possible setup for reducing friction in real-life conditions. With their hydrodynamic, wing-shaped profile, the bands add almost no drag when the air lubrication system is switched off. More importantly, each band can be steered independently, which allows optimization of the air layer by section. Together with the reduced number of compressors needed (1–3 on average), this maximizes the energy efficiency and propulsion power savings achieved with OceanGlide.

Easy installation – on any vessel, at any shipyard

Alfa Laval OceanGlide is quick and cost-effective to implement – not only on newbuilds but also as a retrofit solution. Having no large sea chest and only a small number of freely placed compressors, it demands far less space inside a vessel than other air lubrication systems. Outside, the air distribution bands are fast and easy to install, with minimal hull penetrations and no special training.

OceanGlide – proof in operation

Tharsis Sea-River Shipping was the first to install Alfa Laval OceanGlide. On the coaster M/V Tharsis, the technology has achieved fuel savings of up to 10% through reduced propulsion power. The company sees fluidic air lubrication is as a key technology on its path to more sustainable shipping.

A breakthrough in maritime efficiency

Fluidic air lubrication is a new innovation that significantly reduces propulsion power needs, providing payback through fuel savings in under three years. It was successfully installed on the coaster M/V Tharsis in just one week, improving efficiency with no impact on maneuverability or stability.