Clara series

The Clara range of high-speed separators are specially developed for food, beverage and industrial fermentation applications. The Clara range offer gentle product treatment, high separation efficiency and low power consumption.

The complete range for all needs

Within the Clara range there are models of all sizes, from laboratory or pilot-scale operation to models for large food and beverage as well as industrial fermentation plants with huge capacities. Depending on the model, the Clara separators are available in different designs, from non-hermetic (top fed) to fully hermetic (bottom fed) design.

The smaller Clara models are all skid mounted to facilitate installation, minimize footprint and make them mobile (all the skids have wheels). The skid has all the equipment needed for efficient and reliable operation of the separator. There is a control panel and a pipe rack containing all the necessary components to feed the separator with product and service water.

The larger Clara models are less suitable for skid mounting. Here, the electrical panels for starter and control panel are mounted on a stainless steel, self-supported frame. Product and service water piping with all valves and gauges are mounted on the opposite side of the same frame.

Feed pumps and pumps for solids discharges are available as options for all Clara models. The larger Clara models also have capacity control as option.

Application areas

The Clara series is particularly well suited for clarifying products in

Beverage applications, such as:

- white grape must (free run and press juice)

- young and mature wine (both still and sparkling types)

- tea and coffee extract

- fruit juices (citrus, deciduous and tropical)

Industrial fermentation applications, such as

- micro-algae

- bacteria

- yeast

Features and benefits

The Clara separators have several distinct advantages, depending on the model.

Disc inlet - gentle product treatment

The disc inlet enables the feed to accelerate in a very gentle way. This increases separation efficiency and minimizes foaming.

Oxy-Stop - prevents oxygen pick-up

The liquid seal in the separator outlet prevents oxidation of the product and loss of volatile aromas or CO2.

Fully hermetic design - reduced power consumption

The fully hermetic design is achieved by a combination of a hollow spindle inlet, a hermetic outlet provided by a mechanical seal, and a separator bowl completely filled with liquid.

In addition to maximum separation efficiency and significantly reduced power consumption, the fully hermetic concept prevents any air-liquid interface, which minimizes the risk of foaming.

Hollow spindle design - gentle acceleration

Our unique hollow spindle design ensures the most gentle acceleration of shear-sensitive particles. This leads to maximum separation efficiency and reduced power consumption at the same time.

How it works

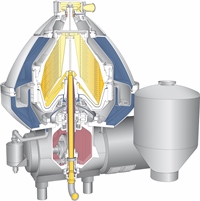

The Clara separator is a two-phase centrifuge system designed for separating solids from liquids. The heart is a self-cleaning disc stack centrifuge with a bowl that rotates around a vertical axis. Inside the bowl is a stack of conical discs where the separation takes place.

Rotating this unit at high speed means that the effect of gravity on solids is replaced by a controllable centrifugal force, which can have an effect more than 10,000 times greater.

When a liquid that contains solid particles is subject to such forces, the solid particles – which are denser – are pressed outwards against the rotating bowl wall.

The special geometry of the bowl ensures gentler acceleration for shear-sensitive agglomerates and particles.