There is no room for shortcuts in ballast water treatment – either from your supplier or in system performance. Alfa Laval provides total solutions in ballast water treatment, built around the industry’s leading treatment technology. By choosing Alfa Laval PureBallast 3, you choose both performance and peace of mind.

Alfa Laval’s offering in ballast water treatment goes far beyond technology. It comprises total solutions to meet your needs, from initial selection and throughout the vessel lifetime.

Time is short when it comes to ballast water treatment. Vessels calling in United States waters need ballast water treatment systems now, and all vessels will require them by 2023. In that brief time, you must find the right solution – but also a supplier who can support you through installation and beyond.

Alfa Laval takes a comprehensive approach to meeting your needs, from today into tomorrow. Our total solutions for PureBallast ensure both the compliance you require and the performance to keep your business running smoothly.

You can count on Alfa Laval expertise and resources in all phases of planning, engineering and working with your PureBallast solution. In addition to our own deep knowledge and experience, we have a worldwide network of trained and capable engineering partners. Everything you require – from feasibility studies and financing to commissioning, training and global service – is readily available.

For a clear picture of what we offer, download our total solutions brochure. There you´ll find a concise overview of how we meet your needs at each step of the way.

A unique combination of capabilities sets PureBallast 3 apart from any other ballast water treatment system.

PureBallast 3 offers unmatched biological disinfection performance in all water salinities: fresh, brackish or marine. This includes water in liquid form at frigid temperatures, as well as the low-clarity conditions in challenging harbours and waterways. Even in low-clarity waters with UV transmittance as low as 42%, the system can perform at full flow, which lets you ballast and deballast efficiently.

PureBallast 3 is fully enclosed, fully automated and thoroughly integrated with the ballast water system. In other words, its operation requires nothing from the crew.

Likewise, PureBallast 3 needs no salt or chemicals, even when operating in fresh water. No dosing is involved, and there are no tanks or ventilation systems needed to manage consumables or residuals.

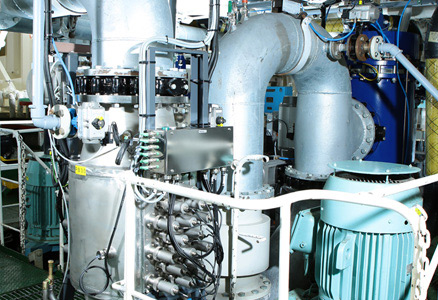

PureBallast 3 is an inline system in which the major components (filter and reactor) are incorporated into the ballast water piping. The reactor, which is made of superaustenetic stainless steel for a lifetime of at least 20 years, has a diameter only marginally larger than that of the piping itself. This creates a highly flexible system with a small footprint, which is especially important for retrofits.

Alfa Laval’s PureBallast 3 offering lets you take full advantage of opportunities in meeting IMO and U.S. Coast Guard (USCG) legislation.

Alfa Laval’s PureBallast 3 offering has all the certifications needed to ensure security and flexibility – today and tomorrow.

PureBallast 3 gives your vessel freedom of movement with the fewest operating limitations. PureBallast 3 systems have IMO and USCG type approvals and are certified for use in fresh, brackish and marine waters. Three-water certification is important beyond rivers or the Baltic and Great Lakes, as many ports considered brackish are actually farther from the marine end of the transition zone and closer to fresh water.

PureBallast 3 has IMO revised G8 type approval, which means systems purchased today can be installed after the stricter IMO guidelines take effect on 28 October 2020. Alfa Laval was the first supplier to receive revised G8 certification and remains one of the few suppliers to have it. When operating in IMO-regulated waters, PureBallast 3 systems make maximum use of their power management and other capabilities.

To address differing needs in United States waters, there are standard and high-power versions of PureBallast 3 under USCG type approval. Standard systems, which utilize flow control in waters with low UV transmittance, are configured as for IMO-regulated waters and provide the option of minimized holding time when operating in USCG-regulated waters. The minimized holding time is just 2.5 hours and is only needed when crossing between Captain of the Port Zones. High-power systems are configured to allow full flow in the vast majority of United States waters.

For future-proof security, PureBallast 3 gives you flexible options if a later change in operating patterns requires you to be able to deballast in United States waters. Vessels that initially installed PureBallast 3 for use only in IMO-regulated waters can easily upgrade to a version of the system with type approval from the USCG.

This is also an important consideration when determining how your choice of treatment system will affect the resale value of your vessel. A vessel that does not offer the potential for USCG type approval will be difficult to sell to any buyer who wants to operate in this key market..

The more waters your vessel has access to, the more business it can bring you.

While marine and brackish waters are the focus for most ship owners, three-water certification is not only for rivers or the Baltic and Great Lakes. Many ports considered brackish are actually farther from the marine end of the transition zone and closer to fresh water. To reach them, you need a system like PureBallast 3, which can treat fresh water without salt or chemical dosing.

Likewise, some ports have near-zero temperatures or low-clarity water. Although UV transmittance levels in harbours usually range from 90% down to 60%, they can sometimes fall even lower. PureBallast 3 handles liquid water at frigid temperatures and can perform at full flow where UV transmittance is as low as 42%.

The less time and energy you devote to ballast water treatment, the more you have for doing business.

The ability to ballast or deballast efficiently is important to your vessel. However, many UV-based treatment systems must reduce their flow in harbours with low-clarity water. This is a result of low UV transmittance which may be further impaired by ineffective UV lamp cleaning.

By contrast, PureBallast 3 can operate at full flow where UV transmittance is as low as 42%. Its effectiveness is maintained by automatic Cleaning-In-Place (CIP), which removes UV-impairing build-up – without effort from the crew or risk of scratching the lamps.

When sailing under most conditions in IMO-regulated waters, PureBallast 3 can operate at just half its potential power, ramping up only for the most difficult low-clarity waters.

Your ballast water treatment system should last – and provide lasting resale value.

If you want your ballast water treatment system to last as long as your vessel, avoid key components that may corrode in seawater conditions. A UV reactor, for example, is a pressure vessel that may need replacing in five years if built with a steel grade like 316L. PureBallast 3 reactors are built with superaustenitic stainless steel which can be expected to last 20 years or more.

Even if you should sell your vessel, your choice of ballast water treatment system is important. Where the vessel can sail will affect its potential range of buyers, as well as the sum they are willing to pay. In addition, buyers value equipment from a stable and recognized supplier, from whom they can count on long-term support worldwide.

No supplier in ballast water treatment is more committed or experienced than Alfa Laval.

Alfa Laval is not only a global marine supplier, but also the most qualified, experienced and knowledgeable supplier in ballast water treatment. PureBallast was the world’s very first commercially available ballast water treatment system, launched originally in 2006.

Our pioneering work with marine biology and UV-based ballast water treatment goes back much further. Since the earliest days of discussion, Alfa Laval has been selected as a consultant on key panels involved in developing standards and educating the market.

Today Alfa Laval has a complete range of solutions for both newbuild and retrofit needs, built on our longstanding work with customers, authorities and scientific bodies. Shipyards, engineering companies and shipowners can expect clear and thorough documentation, as well as expert consultation. Shipowners will also find far-reaching ownership support, including complete services for cost-efficient peace of mind.

Everything Alfa Laval offers – from advice to parts and service – is readily available worldwide.